While hugely popular in the 80’s turbochargers fell out of favor by car manufacturers in the late 90s due to consumer perception that they were high maintenance or unreliable, that coupled with the technology of the time which led to less than optimum performance under certain conditions. Fast forward a decade and the turbo has made a decisive come back. Now used by many of the top car manufacturers including Honda, Ford, Mitsubishi, Dodge and Mazda turbo technology is on the radar of new and used car shoppers and a little education on the basics of how they work is in order.

While hugely popular in the 80’s turbochargers fell out of favor by car manufacturers in the late 90s due to consumer perception that they were high maintenance or unreliable, that coupled with the technology of the time which led to less than optimum performance under certain conditions. Fast forward a decade and the turbo has made a decisive come back. Now used by many of the top car manufacturers including Honda, Ford, Mitsubishi, Dodge and Mazda turbo technology is on the radar of new and used car shoppers and a little education on the basics of how they work is in order.

A turbo is much like any engine accessory in that it is a piece of hardware which mounts on your engine, it’s major difference however is that it’s sole purpose is to increase vehicle performance rather than help make the engine run – it’s an additional piece of hardware added to a working system. Increasingly today the term “performance” is used to describe fuel economy rather than acceleration and top speed and this is how many OEM’s are using turbos, to boost fuel economy.

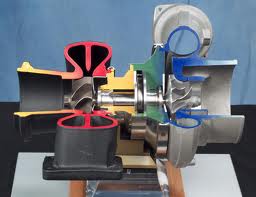

The turbo itself mounts directly onto the engines exhaust manifold, where the hot exhaust gas is being expelled from the engine. Normally that gas would go straight out the muffler and all that energy (in the form of heat) would be lost. With a turbo however a lot of that energy can be reclaimed and used to p ropel the car more efficiently. In a turbo system the exhaust gas first goes through one side of the turbocharger and spins a propeller, called a turbine, much like a water wheel in an old mill house, then it makes it’s way out the muffler. That propeller has a shaft running through it’s center and on the other end is another propeller, called the compressor wheel. This wheel is shaped such that it will suck in air around it’s center, compress it into a smaller area then shoot it out the side and into the engine. That action right there is the reclaiming of the lost exhaust energy. This compression action is favorable because it literally compresses more oxygen molecules into the same cubic inch of air as a non-turbo car. With more oxygen molecules it’s possible to get a “bigger bang” i.e. more horsepower out of every rotation of the engine as long as you inject more fuel to go along with it.

ropel the car more efficiently. In a turbo system the exhaust gas first goes through one side of the turbocharger and spins a propeller, called a turbine, much like a water wheel in an old mill house, then it makes it’s way out the muffler. That propeller has a shaft running through it’s center and on the other end is another propeller, called the compressor wheel. This wheel is shaped such that it will suck in air around it’s center, compress it into a smaller area then shoot it out the side and into the engine. That action right there is the reclaiming of the lost exhaust energy. This compression action is favorable because it literally compresses more oxygen molecules into the same cubic inch of air as a non-turbo car. With more oxygen molecules it’s possible to get a “bigger bang” i.e. more horsepower out of every rotation of the engine as long as you inject more fuel to go along with it.

What? More fuel? I thought the point was to use less fuel Doc. Well it is and here’s why it all makes sense. If you’re producing a large sedan and your market demands a certain amount of power say 300hp then you’ll likely be considering using a V8 engine to achieve that, and that’s exactly what you saw for years, large sedan and trucks were sold with V8’s. The problem is a large V8 requires quite a bit of fuel for normal day to day operations such as starting up, idling, light cruising, and moderate acceleration from a stop light, all that adds up to poor average fuel economy. Now with a turbocharger it is possible to use a small V6, achieve the same ultimate power for towing, up hill pulls and when you have a car full of people but great fuel economy during the day to day around town use, this because the turbo produces that compressed air and the required additional fuel only when you are accelerating hard or have a heavy load or are pulling up a steep grade. So, you get the best of both worlds, great ultimate power when you need it and great fuel economy when you don’t!

Advancements in engine management systems, fuel injection technology and turbocharger design have now largely eliminated the issues that plagued a few turbo cars of the past. Keep an eye out on new car commercials and at the dealer lots and you’ll start to see how popular these wonderful little devices are becoming. They really are one of the best advancements in the efficiency of the good ‘ol internal combustion engine to come around in a long, long time, this time I think they’re here to stay.